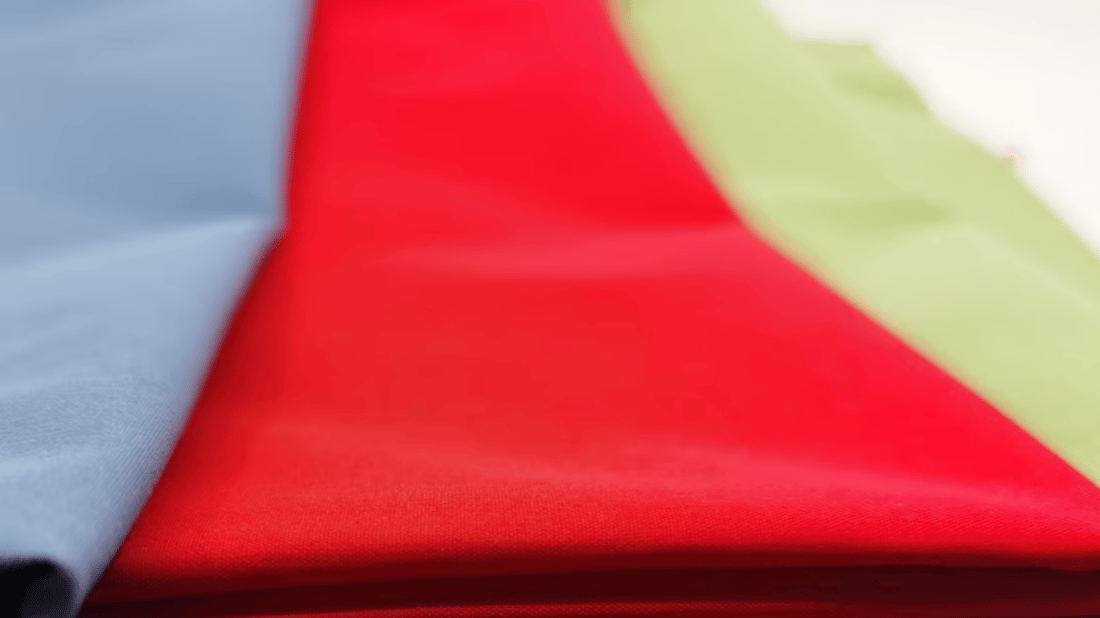

Thermoplastic polyurethane (TPU) coated polyester is widely recognized for its exceptional durability, making it a preferred material in various industries. The inherent strength of polyester combined with the protective TPU layer enhances the fabric's resistance to wear and tear. Understanding TPU coated polyester durability is essential for manufacturers and end-users aiming to select materials that withstand harsh conditions over time.

Enhanced Abrasion Resistance Properties

One of the primary factors driving TPU coated polyester durability is its superior abrasion resistance. The TPU layer acts as a shield, significantly reducing surface damage caused by friction. This makes TPU coated polyester ideal for applications involving frequent contact or rubbing, such as outdoor gear, luggage, and protective clothing.

Waterproofing and Moisture Barrier Benefits

TPU coating enhances the water resistance of polyester fabrics, contributing significantly to durability. The waterproof barrier prevents water penetration, protecting the substrate from moisture-related degradation. This waterproofing property ensures long-lasting performance in environments exposed to rain, humidity, or splashing water.

Resistance to Chemical Degradation

The chemical inertness of TPU coated polyester plays a vital role in its durability. TPU coatings resist damage from a wide range of chemicals, oils, and solvents that would otherwise degrade uncoated polyester. This chemical resistance broadens the fabric's usability in industrial sectors where exposure to harsh substances is common.

UV Protection and Sunlight Stability

Exposure to ultraviolet (UV) rays can weaken fabrics over time; however, TPU coated polyester durability includes excellent UV resistance. The TPU film minimizes damage from sunlight, reducing fading and structural compromise. Products using TPU coated polyester retain strength and appearance longer when used outdoors.

Flexibility and Impact on Durability

A balanced combination of flexibility and toughness characterizes TPU coated polyester durability. TPU coatings maintain their elasticity under stress, allowing the fabric to bend and stretch without cracking or peeling. This flexibility helps absorb impact and resist mechanical stresses in dynamic applications.

Thermal Stability and Heat Resistance

The durability of TPU coated polyester is also linked to its thermal stability. TPU coatings can endure moderate heat without losing properties or deforming. This makes TPU coated polyester suitable for environments with fluctuating temperatures, ensuring that durability is not compromised in thermal stress situations.

Resistance to Microbial and Fungal Growth

TPU coated polyester durability extends to resisting biological degradation. The dense coating layers inhibit moisture retention, a key factor in microbial and fungal growth. This characteristic helps maintain the material’s integrity and hygiene, especially in medical or outdoor applications.

Ease of Maintenance and Longevity

The durability of TPU coated polyester also encompasses ease of maintenance. TPU-coated surfaces are often easier to clean and require less frequent replacement, which contributes to longer service life. This simplification of care determines the overall lifecycle cost benefits of the material.

Environmental Impact on Durability

Environmental factors such as pollution, temperature variation, and physical exposure greatly affect material lifespan. TPU coated polyester durability is reinforced by its resistance to such environmental challenges. This makes it a reliable choice for outdoor products exposed to changing weather and pollutants.

Industry Applications Based on Durability Requirements

The excellent TPU coated polyester durability supports its use in demanding industries such as automotive, sportswear, medical, and outdoor equipment. Manufacturers select this fabric because its durability meets rigorous standards for safety, performance, and longevity, ensuring products perform consistently under tough conditions.

Quote Inquiry

contact us